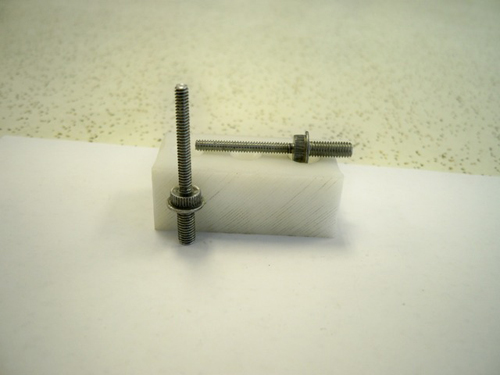

The product highlighted here is a terminal stud requiring thread rolling of 2 different thread sizes, knurling, heat treating and final finishing. Made of aluminum, it features a .406″ head diameter, and .040″ head height. The body/shoulder is .170″ in diameter and .453″ in length, while the shank/tenon has a diameter of .314″/.117″, and a length of .122″/1.116″, with tolerances of +/-.002″.

The initial order of 50,000 pieces was manufactured utilizing our cold heading, threading, and knurling capabilities. Once formed the studs were tumble deburred, vacuum heat treated, and received a clear, iridite finish.

To learn more about this project, or the processes used to manufacture it, contact us directly.