It is the policy of Chicago Rivet & Machine Co. to provide our customers with the highest quality products, at a competitive price. In order to achieve this, the following objectives have been incorporated into the way we perform our normal activities:

- Maintain a constant commitment to satisfy all customer requirements.

- On-time delivery of the highest quality products.

- Never-ending pursuit of our corporate acceptance goal of “Zero Defects”.

Chicago Rivet & Machine Co. operates within a registered IATF 16949:2016 Quality Management System. We bring the following value added processes and services to our HVAC, Electronics and Automotive Customers.

- Full AIAG compliant PPAP.

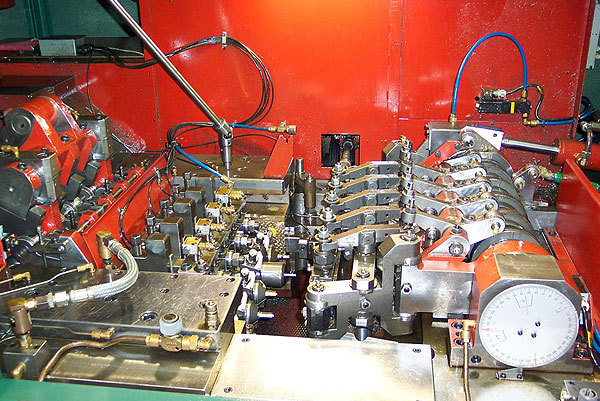

- Electronic process monitors with one piece conveyor discharge.

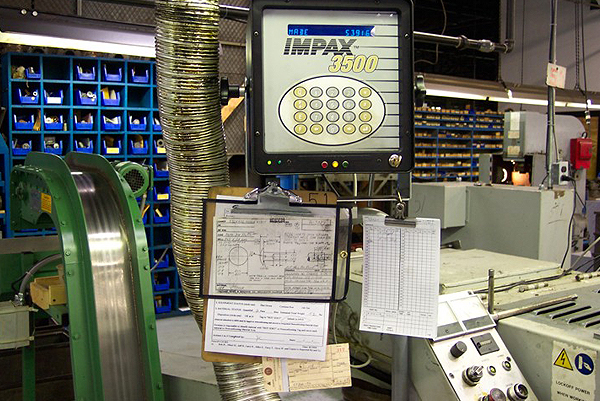

- A complete electronic inspection record for each part control plan production lot, including raw material receiving, in-process dimensional recording, hardness and coating thickness tests and inspections.

- AIAG measurement systems analysis supported by Gage R&R Studies and N.I.S.T.

- X bar and R charts for every cold heading process monitoring tooling wear.

- Predictive and Preventive Maintenance with established Process Capability Studies and Cp Indices.

- Dimensional and coating thickness using current image measurement system and x-ray fluorescent technology.

- “Fast Response” to all customer concerns / complaints. A take care of the customer first philosophy.